Spiral Binding vs Wire-O Binding: An Updated Guide

What sets spiral binding apart from wire-o binding in your printing projects? Uncover the crucial aspects in the ‘spiral binding vs wire-o binding’ debate to determine which is the ideal choice for your needs.

When it comes to choosing the right binding method for your printing project, the details matter. In this updated guide, we explore the specifications of spiral binding and wire-o binding, two popular choices that offer unique advantages and considerations.

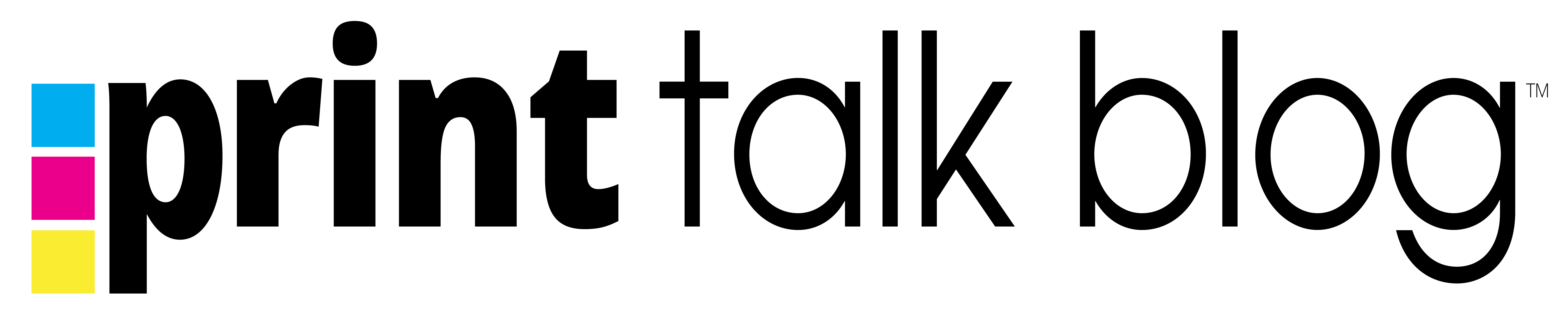

Spiral Binding: A Versatile Choice

Spiral binding, known for its flexibility and durability, is ideal for a wide range of projects like manuals, journals, and reports. The key feature here is the plastic coil, which not only withstands frequent use but also allows pages to rotate 360 degrees. This functionality is perfect for projects requiring frequent referencing, as it enables easy reading and writing without occupying much space.

The Spiral Binding Process: How It Works

Spiral bound printing is single sheets of paper printed on both sides, cut down to trim size and collated in page number order. Then a continuous plastic coil loop shaped like a long spring passes through a row of punched holes at the end of the printed piece. The binding can be on the left or top of the project, making it a good option for both booklets and calendars. Spiral Bound books are easy to handle and lie flat when open (180 degrees).

An added bonus to the spiral binding option is that there are different coil sizes and diameters available to accommodate your project. These spiral coils can bind pages up to 2 3/4 inches thick. Our standard color for spiral binding is black.

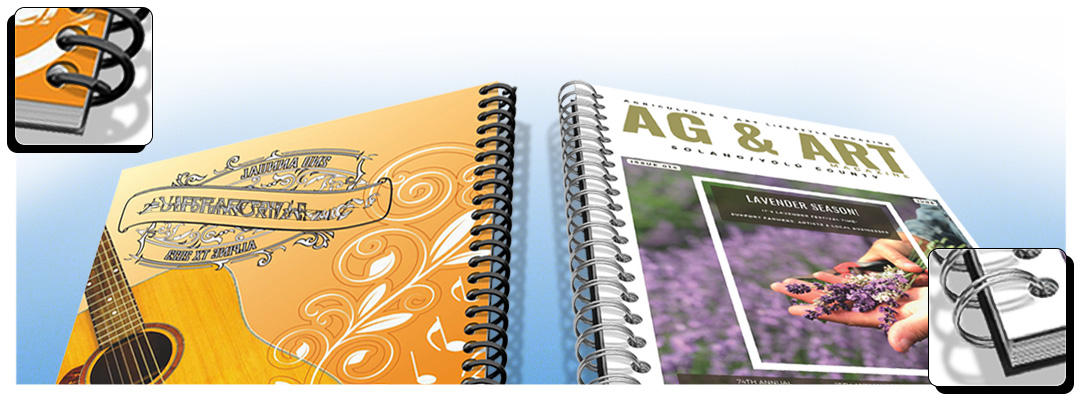

Popular Spiral Book Binding Types

Spiral binding, renowned for its practicality and durability, is a popular choice for a variety of book types. Among the most common are cookbooks, which benefit from the binding’s ability to lay flat for easy recipe viewing. Educational materials such as workbooks and training manuals also frequently utilize spiral binding, as it withstands frequent use and allows for easy note-taking. Additionally, personal planners and journals are often spiral-bound, providing flexibility and ease of use for everyday planning and writing. The versatility of spiral binding makes it an ideal option for these and many other types of books, where functionality and user-friendliness are key.

The Wire-O Binding Edge

Wire-O Bound books are used for more formal, organized, and professional presentations of information. Similarly, to spiral binding, the pages can be turned 360 degrees around on themselves without damaging the spine. Wire binding uses a looped metal wire. This wire is stronger than the plastic alternative. This professional looking wire makes it great for fine art photography calendars as well as business reports, documents, cookbooks, or directories.

The Wire-O Binding Process

Wire-O binding is single sheets of paper printed on both sides, cut down to trim size and collated in page number order. The wire, often referred to as wire-o or twin-loop / double-loop binding, has pre-formed pairs of two small loops of wire that run along a c-shaped spine that looks like a comb. These wire loops are inserted through each of the square holes that have been punched through the edge of the printed book’s cover and pages which allow the pages of your book to line up precisely. A wire closer squeezes the spine until it is round and securing the cover and pages. The binding can be on the left or on the top, depending on how the project is designed.

Our standard color for wire binding is black. Wire-o binding requires a lower page count than spiral binding up to 1 ¼ thick.

Spiral Binding vs Wire-O Binding: Design Considerations

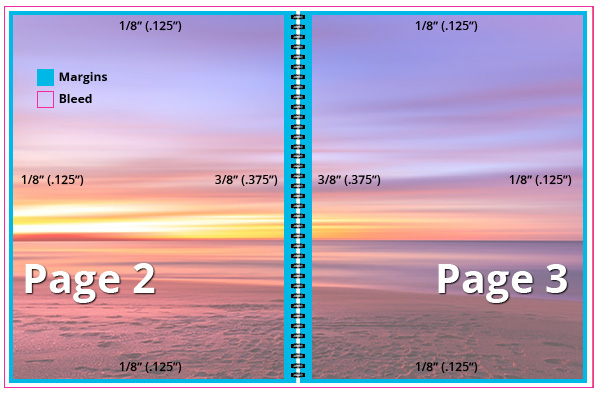

While spiral and wire-o bindings have their unique characteristics, they share common design considerations. For instance, ensuring sufficient margin on the binding side is crucial to accommodate hole drilling. Full bleed images work well, but crossovers should be avoided due to potential misalignments.

Margins: Be mindful that there will be hole drilling on the binding side during the design process. An easy way to prepare for this is to set your binding-side margins to 3/8”.

Crossovers, or images that span two inside spread pages, are not recommended for spiral or wire-o binding. This is because the gap between page spreads and the spiral or wire will create an obtrusive break in a full crossover spread. Full bleeding images are fully acceptable.

Spine Printing: You cannot print on the spine of a spiral or a wire-o book.

Spiral Binding vs Wire-O Binding: How to Choose Which One?

- Project Purpose: Consider how the end-user will interact with the product. Spiral is more durable and casual, while wire-o offers a more formal appearance.

- Aesthetics: Decide on the look you want. Spiral binding provides a range of color options for the coils, whereas wire-o binding offers a more classic, metallic look.

- Durability: If your project is meant for rigorous use, spiral binding might be a better choice due to its robustness.

- Page Count and Thickness: Wire-o binding suits thinner projects, while spiral binding can accommodate thicker ones.

Specification Tips When Ordering:

- Clear Cover and Vinyl Back: At PrintingCenterUSA, we offer the option of having a clear plastic cover and/or a black vinyl back cover for spiral and wire-o binding. These options are there to provide extra durability to your printed project. This works exceptionally for projects such as cookbooks or employee handbooks.

- Pages: Spiral and wire-o orders must be in two page increments. Save your print-ready PDF with each single facing page for your project, including the front and back cover. Upload pages in this order:

- Size: Our standard sizes for spiral and wire-o are as follows:

|  |  |

|

Portrait 8.5 x 11 5.5 x 8.5 6 x 9 4.25 x 11 |

Landscape 11 x 8.5 8.5 x 5.5 9 x 6 | Square

6 x 6 8 x 8 |

If you do not see the size you need, click the “Custom Size” button on the pricing tool and enter your custom size.

*Height Should Be Between 4” – 9”; Width Should Be Between 5” – 12”

- Paper: For Spiral and Wire-o Binding, we recommend 100# Gloss cover and 100# Gloss text. However, if the project is a workbook or journal that is meant to be written in, then we recommend 70# uncoated text.

Conclusion

In conclusion, the choice between spiral binding vs wire-o binding boils down to your project’s specific needs and aesthetic preferences. Spiral binding offers robustness and flexibility, perfect for frequently used documents, while wire-o binding brings a sleek and professional finish, ideal for formal presentations. Understanding these nuances will help you make an informed decision that aligns with the purpose and desired impact of your print project.

At PrintingCenterUSA, we’re committed to helping you navigate these choices, ensuring that your project not only meets but exceeds expectations. Whether it’s the durability of spiral binding or the elegance of wire-o binding, our team is here to guide you through each step, guaranteeing a finished product that perfectly encapsulates your vision. Choose wisely, and watch your printed creations come to life with the binding that best suits them!